Pig Feed Conversion: When Less Is More

Young Animal : Nutrition

Feed conversion is a measurement of the amount of feed needed for an animal to gain one pound of bodyweight.

A low feed conversion ratio indicates your pigs are efficiently turning feed into bodyweight. A high feed conversion ratio means your pigs might not be using the full potential of your feed program.

As an example, you might feed 665 pounds of feed to a pig in the weeks it weighs between 40 pounds and 280 pounds. You would calculate the ratio as “665 pounds of feed divided by 240 pounds of gain for a score of 2.77.”

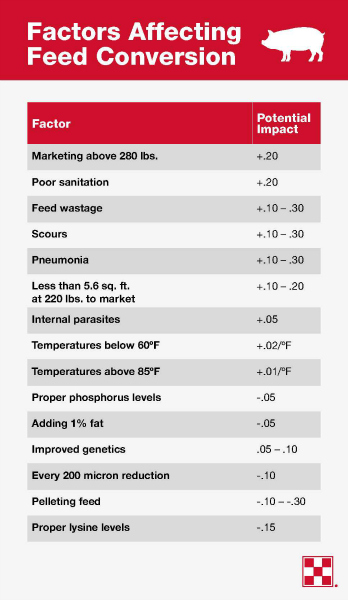

To help you better see the potential differences between the factors affecting pig feed conversion ratios, the swine nutrition experts on Team Purina have compiled data demonstrating the potential impact of some of the factors.Factors that could negatively impact pig feed conversion ratios

(Higher scores, less efficient conversion)

A low feed conversion ratio indicates your pigs are efficiently turning feed into bodyweight. A high feed conversion ratio means your pigs might not be using the full potential of your feed program.

As an example, you might feed 665 pounds of feed to a pig in the weeks it weighs between 40 pounds and 280 pounds. You would calculate the ratio as “665 pounds of feed divided by 240 pounds of gain for a score of 2.77.”

To help you better see the potential differences between the factors affecting pig feed conversion ratios, the swine nutrition experts on Team Purina have compiled data demonstrating the potential impact of some of the factors.

- A symbol indicates higher (less efficient) feed conversion score.

- A – symbol indicates lower (more efficient) feed conversion score.

Factors that could negatively impact pig feed conversion ratios

(Higher scores, less efficient conversion)

- Feed wastage has been shown to have one of the greatest potential impacts on feed conversion out of all the factors. Feed waste includes loss to rodents or birds, spoiled feed and feed sorted out and refused by pigs.1

- Have you noticed how your appetite drops when you’re sick? This happens because our bodies shift energy to combat illness. This same thing happens to pigs when their immune systems use energy to fight the cause of the illness. Diseases or irritation to the gastrointestinal tract can limit the way the gut absorbs nutrients, further limiting energy for growth.2 Irritation caused by parasites could cause a similar response.3

- When you market pigs at weights greater than 280 pounds, you lose the opportunity to maximize feed efficiency because pigs at that weight have been shown in studies to be less efficient at converting feed to lean meat.4

- Poor sanitation can negatively impact feed efficiency because pigs could need to use energy to fight off pathogens rather than to grow efficiently.1 When striving for a lower pig feed conversion ratio, it’s important to maintain a comfortable environment for your pigs.

- If the temperatures are higher or lower than optimal, your pigs could be using energy to maintain body temperature rather than to grow or build body mass.4

Factors that potentially improve pig feed conversion ratios

(Lower scores, improved feed efficiency)- Optimizing phosphorus in pig diets is a balancing act. Pigs need adequate phosphorous for skeletal development and optimal energy use. If pigs are fed more phosphorus than they can use, the mineral is excreted in waste.4

- Feed efficiency is one of many factors you can choose when selecting genetics for your herd.5

- Pelleting feed can help support pig performance in many ways compared to feeding meal feeds.6 The pelleting process can improve feed handling; quality pellets (with limited fines) prevent pigs from sorting feed and wasting it. Pelleting feeds also reduces particle size for improved digestibility.7 Read more about the advantages of pelleted feeds.

- Lysine is the limiting amino acid in grain-based swine diets because without it, pigs cannot efficiently use the other essential amino acids needed for optimal growth and development. Grain-based diets alone cannot provide enough lysine for optimal performance.4

1 Patience, John F., editor. Feed Efficiency in Swine. Wageningen, The Netherlands, Wageningen Academic Publishers, 2012.

2 Holtkamp, Derald, Hans Rotto, and Steve Parker. "Costs of Swine Disease: Impacts of Feed Efficiency." ISU Swine Disease Conference for Swine Practitioners, 2007, Ames, Iowa.

3 Straw, B.E., "G91-1049 Controlling Internal Parasites in Swine" (1991). Historical Materials from University of Nebraska-Lincoln Extension. Paper 1153.

4 Purdue University Cooperative Extension. Pork Industry Handbook. Purdue University, 2010.

5 Reese, Duane E. National Swine Nutrition Guide. University of Nebraska, 2010.

2 Holtkamp, Derald, Hans Rotto, and Steve Parker. "Costs of Swine Disease: Impacts of Feed Efficiency." ISU Swine Disease Conference for Swine Practitioners, 2007, Ames, Iowa.

3 Straw, B.E., "G91-1049 Controlling Internal Parasites in Swine" (1991). Historical Materials from University of Nebraska-Lincoln Extension. Paper 1153.

4 Purdue University Cooperative Extension. Pork Industry Handbook. Purdue University, 2010.

5 Reese, Duane E. National Swine Nutrition Guide. University of Nebraska, 2010.

6 Hancock, J.D. and K.C Behnke. Use of ingredient and diet processing technologies (grinding, mixing, pelleting and extruding) to produce quality feeds for pigs. Swine Nutrition, Second edition. Edited by A.J. Lewis and L.L. Southern 2001. pp 469-497.

7 Grumm, M.C., S.L. Colgan and K.J. Bruns. Effect of out-of-feed events and diet particle size on pig performance and welfare. Journal of Swine Health, 16, 2008. (2):72-80.

7 Grumm, M.C., S.L. Colgan and K.J. Bruns. Effect of out-of-feed events and diet particle size on pig performance and welfare. Journal of Swine Health, 16, 2008. (2):72-80.

_1.png?width=300&height=430&ext=.png)

.png?width=300&height=430&ext=.png)